CellTec Systems Unveils New Research to Optimize Flavor and Nutrition in Cultivated Meat Production

The industrial scaling of cultivated meat faces a key challenge: the economical production of tasty and nutritious cell mass, particularly in terms of quantity and quality. CellTec Systems is now presenting research results that point to new approaches. By exploiting the natural plasticity of primary cells, it is possible to produce both the nutritional profile and the flavor-giving fat components efficiently and without genetic modification, the company states. Muscle Similarity …

MicroHarvest Selects Germany for First Large-Scale Production Plant

German biotech MicroHarvest, a producer of protein ingredients via biomass fermentation, has selected Industriepark Leuna in Saxony-Anhalt as the location for its future production plant. The company utilizes regional agri-food side streams for its process. Federal grant of €5.46M awarded for industrial energy efficiency The planned facility is designed for an annual capacity of 15,000 tonnes, with a planned mid-range double-digit million EUR investment in the region and the creation …

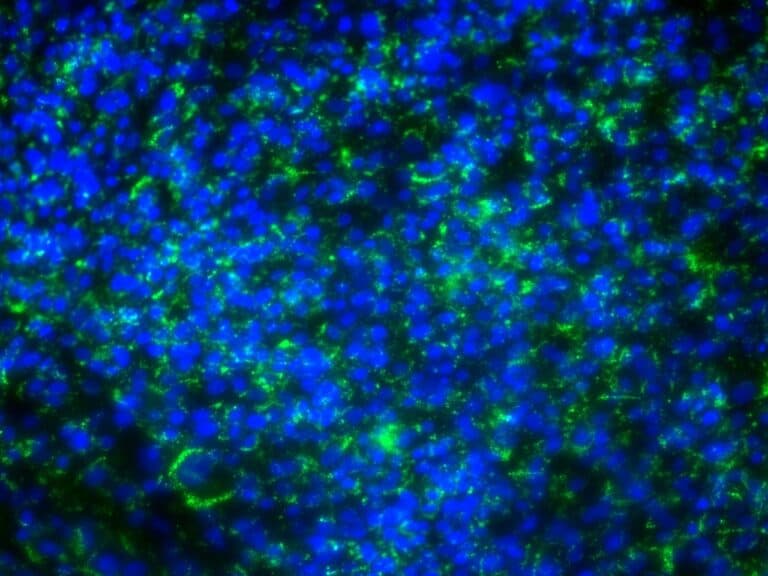

Aleph Farms and Roslin Technologies Demonstrate Cross-Platform Compatibility for Cell Cultivation

Aleph Farms, a cellular agriculture company developing a scalable biomanufacturing platform for the food and broader bio-based industries, announced the successful completion of the first phase of a collaboration with UK-based biotechnology company Roslin Technologies, a leading developer of advanced animal cell lines for cellular agriculture applications. “This milestone demonstrates, for the first time, that cells developed by an external organization can grow successfully using Aleph Farms’ proprietary growth medium, …

EAT BEER Scales Technical Development of Spent Grain Protein Following Initial Trials

EAT BEER, a biotechnology company specializing in the transformation of side streams from the brewing and food industries into fungal protein raw materials for the food industry through fermentation, has entered the pilot phase of its production. The sister company of Störtebeker Braumanufaktur is a spin-off from the research project MaltFungiProtein, which is funded by the German federal government, and specializes in the fermentation of brewery by-products using fungi. Since …

Kynda Opens Industrial Fermentation Site to Scale Protein from Food Sidestreams

Kynda, a biotechnology company specializing in fermentation-based protein production, has opened a new research and production facility in Jelmstorf, Lower Saxony. The 720-square-meter site combines laboratory and production operations, with the aim of converting underutilized food processing sidestreams into fungal mycelium for use as protein. The facility includes 360 square meters of R&D space focused on process optimization and substrate adaptation, alongside a production area with 40,000 liters of fermentation …

CREMER Launches FermBase, a New Brand Providing a One-Stop Shop for Fermentation Media

CREMER Group, a specialist in the trade, processing, and transport of raw and basic materials, has launched a new brand called FermBase to serve as a competence center and one-stop shop for fermentation media. FermBase aims to address key challenges in the next-generation and precision fermentation industries, including complex sourcing requirements, fragmented feedstock markets, raw material costs as a major driver of process costs, and limited scalability across the supply …

Analysis: Alternative Proteins Could Add €111B a Year to the EU’s Economy by 2040

A new analysis by systems change company Systemiq, supported by GFI Europe, has found that plant-based foods, cultivated meat, and fermentation could add €111 billion a year to the EU’s economy by 2040 if treated as a strategic priority. This is comparable to the GDP contribution of Europe’s wine sector. Furthermore, the industry could support 414,000 high-quality jobs in areas such as science, agriculture, and logistics, if given policy support …

Cell4Food Partners With Algocell to Optimize Its Cell Cultivation Process

Cell4Food, a Portuguese company producing cultivated marine foods, has announced a partnership with Algocell, which has developed an AI-powered bioprocess modeling platform. The partnership will integrate Cell4Food’s cell cultivation technology stack, BlueCell™, with Algocell’s AI-powered bioprocess modeling platform, Algocell P™. The aim is to accelerate Cell4Food’s process development and optimization. By integrating Algocell’s Digital Twin technology, Cell4Food hopes to complete and optimize a full cell cultivation process, creating an optimal …

Revo Foods Applies 3D Structuring Tech to Cultivated Fish in Partnership with Atlantic Fish Co

Atlantic Fish Co and Revo Foods have entered a collaboration to develop hybrid seafood products that combine cultivated whitefish cells with mycoprotein-based structuring technology. The two companies are testing whether mycoprotein matrices can be used as a scalable platform to support cultivated cell integration for whole-cut seafood formats. Atlantic Fish Co, based in North Carolina, has developed proprietary whitefish cell lines and tissue engineering processes. Austrian startup Revo Foods contributes …

Innocent Meat Raises €6M to Develop Automated Cell-Based Meat Platform

German biotechnology company Innocent Meat has secured €6 million in a new financing round to support the development of its automated production technology for cultivated meat and to begin construction of a demonstration facility. Founded in 2020 by Laura Gertenbach and Patrick Inomoto, Innocent Meat focuses on industrial-scale production systems for cell-based meat. The company’s platform is designed to enable meat processors to produce cultured meat using an integrated system …