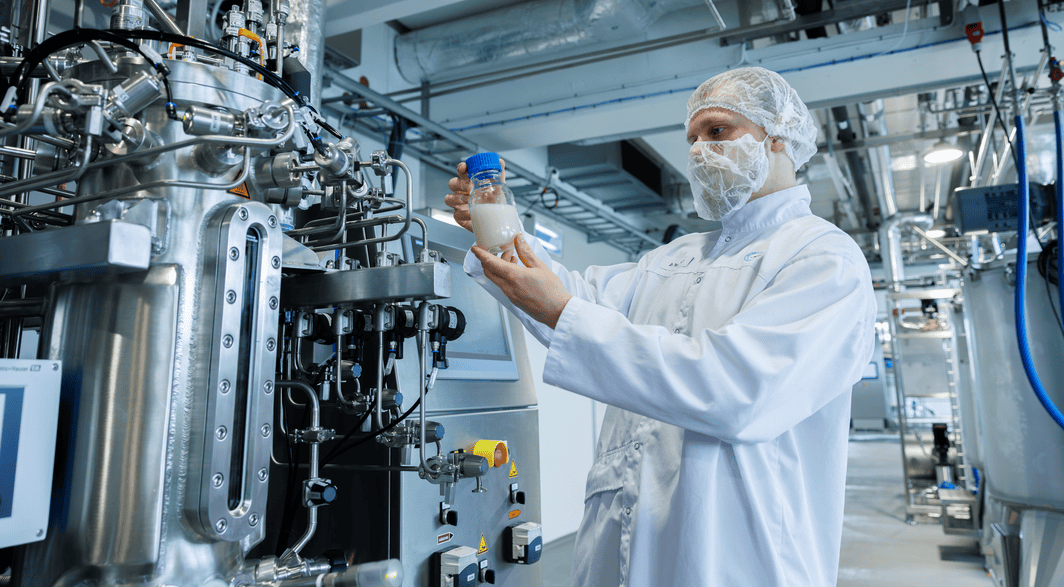

Tetra Pak Strengthens Fermentation Technology with Bioreactors.net Acquisition

Tetra Pak Processing Equipment SIA has acquired Bioreactors.net, a Latvia-based company specializing in the design and manufacturing of bioreactor systems. Established in 1996, Bioreactors.net has nearly 30 years of experience providing biomass and precision fermentation solutions, particularly in the production of proteins and other food ingredients. As part of the acquisition, approximately 15 employees from Bioreactors.net will join Tetra Pak. Bioreactors.net’s systems are used across various stages of production, ranging …

New B2B Marketplace Launched to Address Cultivated Meat Industry’s Procurement Challenges

A new B2B marketplace, Cellbase, has launched to streamline procurement for companies in the cultivated meat sector. The platform is designed to simplify the sourcing process for the specialized materials and equipment needed in cultivated meat production, such as bioreactors, growth media, scaffolds, and cell lines. The cultivated meat industry has faced significant procurement challenges due to the fragmented nature of its supply chain. According to David Bell, the founder …

Asterix Foods Raises $4.2M to Disrupt Protein Production with Affordable Plant Cell Technology

Asterix Foods, a food-tech startup based in Tel Aviv, has raised $4.2 million in a Seed funding round led by CPT Capital, with additional backing from ReGen Ventures, SOSV, Grok Ventures, and the Israeli Innovation Authority. The company, which emerged from stealth mode today, is focused on transforming the production of bioactive proteins, which are integral to the food and biotechnology sectors. Traditional protein production faces high costs The challenge …

Scotland Gets Its First Open-Access 300L Fermenter Thanks to £847K Grant

Scotland’s biotechnology sector is celebrating the launch of the country’s first open-access 300-litre fermenter, which has been installed thanks to an £847,000 grant from the national economic development agency, Scottish Enterprise. The fermenter, which is a type of bioreactor used to cultivate microorganisms, is located at the Industrial Biotechnology Innovation Centre’s (IBioIC) FlexBIO scale-up facility at Heriot-Watt University in Edinburgh. It expands IBioIC’s scale-up capabilities significantly, increasing upstream bioprocessing capacity …

Meatly’s Low-Cost Bioreactor Could Slash Cultivated Meat Production Expenses by 95%

Cultivated meat company Meatly has completed commissioning and its initial cell growth tests using a newly developed pilot-scale bioreactor with a 320-liter capacity. Designed in-house by Meatly’s research and development team, this bioreactor is priced at approximately £12,500, significantly lower than the typical pharmaceutical-grade bioreactors currently used in the cultivated meat sector, which can cost around £250,000 or more. Culture media cost breakthrough Meatly’s chief scientific officer, Helder Cruz, explained, …

n!Biomachines and Siemens Focus on Simplifying Biomanufacturing for Alternative Proteins

At the ongoing Hannover Messe, The Cultivated B and Siemens have teamed up to present advancements in biomanufacturing for the alternative protein sector. The companies are showcasing their AUXO V® bioreactor, a key technology aimed at scaling alternative protein production through economically sustainable methods. n!Biomachines, a subsidiary of The Cultivated B, is at the forefront of developing bioreactors designed for the food industry and other sectors. These bioreactors play a …

Culture Biosciences Offers a Mobile Solution for Faster and More Scalable Biotech Development

Culture Biosciences has introduced a new solution for biotech and cellular agriculture teams: the Stratyx 250, a mobile, cloud-based bioreactor system designed to streamline process development. This new bioreactor promises to cut down on development time and costs, improve scalability, and simplify bioprocess monitoring and control, offering key benefits for growing companies in the cellular agriculture space. The Stratyx 250 is tailored to meet the specific needs of biotech companies, …

Allbiotech Introduces Cost-Effective Bioreactor for Precision Fermentation Research

Spanish biotech startup Allbiotech Biotechnologies has completed the first production run of its Genesys V1 bioreactor, a lower-cost alternative for precision fermentation research. The company aims to make bioreactor technology more accessible to food tech startups, research institutions, and universities by offering a system priced at one-third of the cost of traditional pharmaceutical bioreactors. With a 1-liter glass vessel, integrated sensors, and five peristaltic pumps, Genesys V1 is designed for …

Guest Post: Making Cultivated Meat Scalable and Sustainable with New Bioprocess Technology

The global food system is at a pivotal juncture, with growing populations, environmental pressures, and rising demand for sustainable, ethical protein sources converging to create both challenges and opportunities. Cultivated meat, a promising innovation, allows the production of real animal protein without the environmental burden. However, scaling cultivated meat to commercial viability while ensuring food safety and reducing environmental impact remains a key industry challenge. In the following guest post, …

Believer Meats & GEA Partner to “Produce Cultivated Meat Products at the Right Cost”

Israel’s Believer Meats and GEA Group, one of the world’s technology and equipment suppliers for food manufacturers, have announced a strategic partnership to make cultivated meat more affordable, accessible, and sustainable. The collaboration will focus on co-developing technologies and processes to improve the unit economics and sustainability of cultivated meat production, starting with chicken and potentially expanding to other products. The collaboration follows Believer Meats’ recent MOU with AGWA, Abu Dhabi’s new food …