The global food system faces a pressing need for sustainable innovation, driven by environmental and ethical concerns associated with conventional animal agriculture. While initiatives to enhance efficiency and reduce waste are crucial, the development of novel food products, particularly cultivated meat, offers a promising way to reduce environmental impact and diversify food sources. Cultivated meat, produced through the in vitro cultivation of animal cells, offers a unique approach to produce protein, circumventing many of the traditional challenges associated with livestock farming.

Despite significant investment and over 180 companies actively engaged in cultivated meat research and development, the path to market remains challenging. Stringent regulatory frameworks and the substantial time and costs associated with product approval [1] are major hurdles. Ensuring safety for human consumption is paramount, requiring rigorous testing of cell lines, growth media, and the entire production process. For example, the first cultivated meat product approved in Singapore underwent a three-year review, highlighting the demanding nature of regulatory approval [2].

The recent regulatory approval of a cultivated meat product by FSANZ (Food Standard Australia New Zealand) highlighted the extensive data required to gain market access [3]. Regulatory landscapes differ widely across jurisdictions. In the United States, the Food and Drug Administration (FDA) oversees cell collections, cell banks, and cell growth, while the United States Department of Agriculture (USDA) manages harvesting, processing, and labelling for specific animal species. The European Union’s approval process, governed by the European Food Safety Authority (EFSA), is characterized by strict legislation concerning novel foods and genetically engineered products. These differences illustrate the challenges in achieving international harmonization, which can impede global market access and trade.

Central to regulatory scrutiny are food safety and health concerns. The process begins with a comprehensive assessment of the cell line itself, including its provenance, genetic stability over multiple passages, absence of tumorigenicity, and freedom from pathogens such as bacteria, mycoplasma, fungi, and adventitious viruses. Compliance with regulations like the Nagoya Protocol, which ensures fair and equitable sharing of benefits from genetic resources and CITES (the Convention on International Trade in Endangered Species of Wild Fauna and Flora) which governs the use of products derived from endangered species, adds layers of complexity to cell line sourcing and use.

Considerations from the pharmaceutical industry, such as growth under animal-derived component-free conditions and scalability in large-scale bioreactors, are also becoming increasingly relevant for novel food product development. These are some reasons why regulatory bodies are leaning towards methodologies, already applied in the pharmaceutical industry, which are for novel food developers and companies difficult to implement.

Nuvonis Technologies offers a unique solution to support novel food companies by directly addressing these critical regulatory hurdles. Nuvonis specializes in the development and provision of cell lines manufactured under Good Manufacturing Practice (GMP) standards. Each cell line is thoroughly tested, strictly adhering to pharmacopeial regulations according to ICH (International Committee of Harmonization) Q5D guidelines. Nuvonis cell lines have already supported successful market approvals for novel foods and have also been applied in the production of medicinal products for human and animal health.

Nuvonis services extend beyond providing high-quality cell lines; it includes comprehensive documentation and a fully traceable provenance for each cell line, helping to reduce risk in the approval process for novel food companies.

Furthermore, Nuvonis tests its cell lines across a range of cultivation systems, from spinner flasks to high cell density bioreactors, ensuring both scalability and compatibility with industrial production processes.

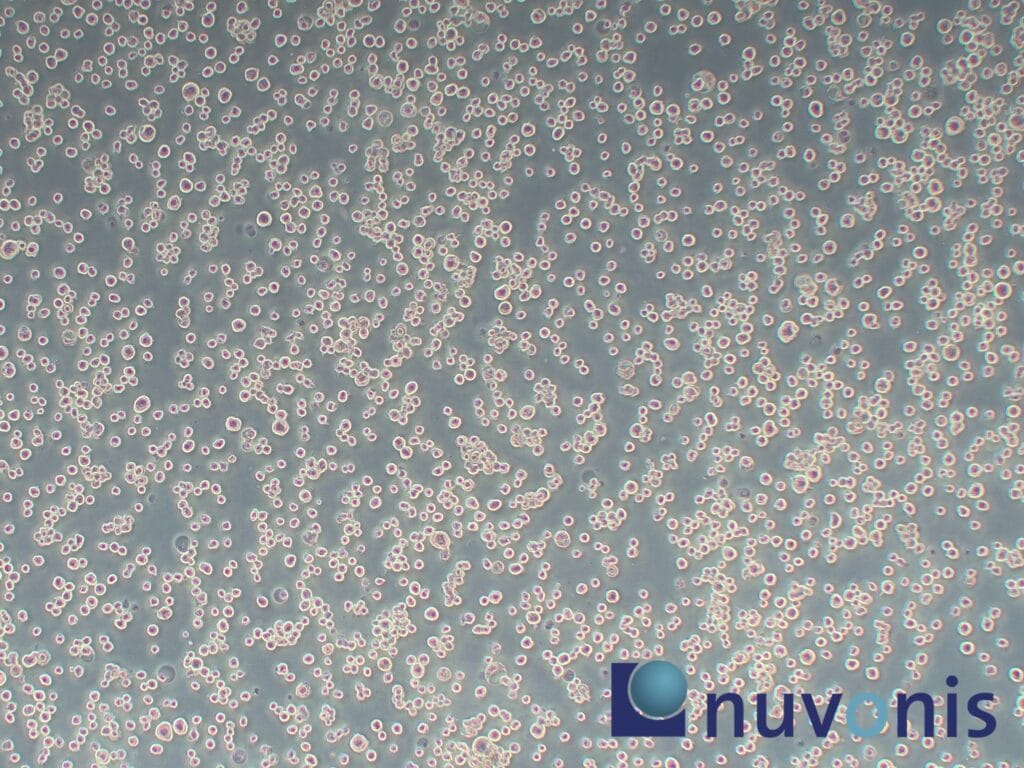

For example, Nuvonis’ proprietary quail cell line (Coturnix japonica), CCX, is available in GMP quality, and can be grown in either adherent or in suspension culture. The suspension cells have a doubling time of 24 hours and have been successfully cultivated in 10 000-liter stirred bioreactors, or to cell densities of 2 x 107 cells per mL in perfusion bioreactors. CCX cells are successfully used and approved by the regulatory authorities to produce cultured meat and in pharmaceutical production.

By providing readily available, thoroughly characterized cell lines and offering tailored cell line development and banking services, Nuvonis Technologies empowers novel food companies to navigate complex regulatory requirements with greater efficiency and confidence, accelerating their path from concept to market.

Based in Vienna, Austria, Nuvonis specializes in advancing biopharmaceutical and cellular agriculture development through innovative cell line solutions, customized virus agent generation for clinical testing, robust process development, and regulatory and manufacturing support. This end-to-end approach streamlines the entire production journey, from early research to clinical readiness or market entry.

By combining scientific innovation, regulatory compliance and scalable production, cultivated meat is becoming not just an innovation but a safe and sustainable protein source for the global food supply.

Learn more on nuvonis.com or get directly in contact with us, office@nuvonis.com.

[1] Mahya Tavan, Nick W. Smith, Warren C. McNabb & Paul Wood (21 Feb 2025): Reassessing the sustainability promise of cultured meat: a critical review with new data perspectives, Critical Reviews in Food Science and Nutrition, DOI: 10.1080/10408398.2025.2461262

[2] “Cultured Meat Market Size By Source, By End-Use, Industry Analysis Report, Regional Outlook, Growth Potential, Price Trends, Competitive Market Share & Forecast, 2023 – 2032”, 2022, Global Market Insights[3] A1269 – Cultured Quail as a Novel Food; A1269 – Cultured Quail as a Novel Food | Food Standards Australia New Zealand