Finnish air-based protein producer Solar Foods has announced that its first commercial-scale facility, Factory 01, has reached production parameters that enable it to operate at full design capacity.

Factory 01 will now be able to produce 160 tons per year of Solar Foods’ protein, Solein, after its productivity reached 1 g/l/h and its energy efficiency value (O2/CO2) reached 2.7. Production was successfully ramped up following a maintenance break this summer.

Before the break, the facility had produced Solein continuously for eight months through gas fermentation technology, using carbon dioxide and hydrogen as the main raw materials. At full production capacity, Factory 01 is claimed to produce as much protein per day as a 300-cow dairy farm.

“Globally unique production facility”

Solar Foods now plans to develop the productivity and energy efficiency of Factory 01 even further by implementing improvements demonstrated at its pilot facility. This will increase annual design capacity from 160 tons to 230 tons in 2026, while significantly lowering the production cost of Solein.

“Factory 01 is a globally unique production facility and hydrogen fermentation platform,” said Petri Tervasmäki, Chief Technology Officer at Solar Foods. “It’s a historic first of its kind for cellular agriculture unlike anything that’s ever been built before, incorporating state-of-the-art technology into protein production. Successfully scaling our technology up a hundredfold compared to our pilot facility’s scale and ramping up the production to reach the full design capacity even earlier than planned are major milestones on the journey of Solein’s commercialisation.”

Implementing Factory 02

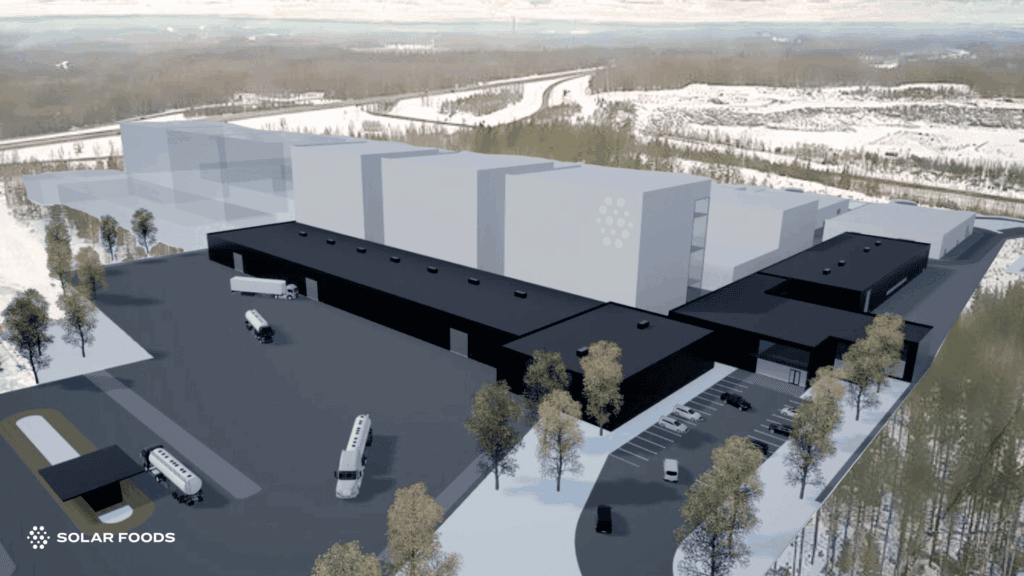

Solar Foods has also announced plans to proceed with the pre-engineering and implementation of its Factory 02 facility with a network of strategic partners. The site’s first phase will have a design capacity of 3.2 kilotons per year, increasing to 6.4 and potentially 12.8 kilotons in two further phases.

Solar Foods says the use of strategic partners will significantly reduce financing needs for the implementation of Factory 02. A decision on the location of the facility is expected to be made by the end of the year.

Last month, Solar Foods submitted a GRAS (Generally Recognized as Safe) notification to the United States Food and Drug Administration (FDA), aiming to obtain a no-questions letter for Solein. Shortly afterwards, the company announced the development of a mayonnaise product using Solein as an egg yolk replacement.

“We have explored various options and found leading partners in their respective fields to implement Factory 02,” said Ilkka Saura, CFO of Solar Foods. “Utilising partners would facilitate the company’s capital acquisition, and at the same time, the return on invested capital would significantly improve.”