A recent study in Food Hydrocolloids has explored the use of chickpea protein (CP) as a material for creating scaffolds to support the growth of cultured meat. cell growth conditions, the study points to the potential of chickpea-based scaffolds to be a part of the future of cultured meat. Scaffolds play a crucial role in the production of cultivated meat by providing structural support for cells as they grow, helping replicate the texture of traditional meat.

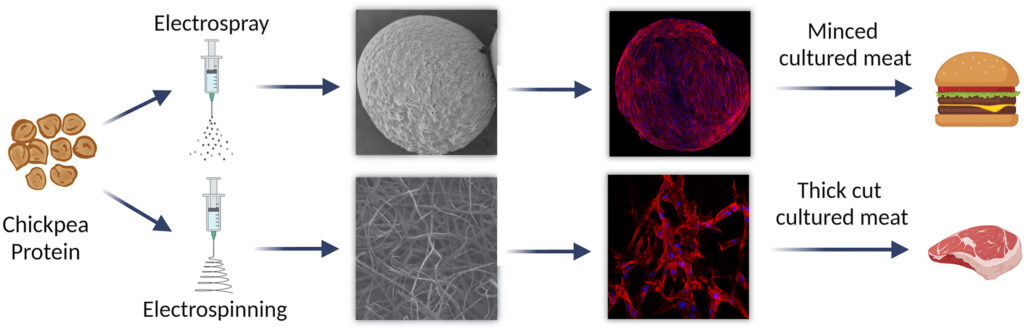

In this study, researchers developed two types of scaffolds using chickpea protein: edible microcarriers and fibrous scaffolds. These scaffolds were created using electrospray and electrospinning technologies, both of which are scalable and cost-effective methods that could be applied to large-scale production.

Fibers that mimic muscle structure

The edible microcarriers were produced using electrospray technology, which resulted in spherical particles with an average diameter of 577 micrometers. These microcarriers provide a stable surface for cells to adhere to and grow. The fibrous scaffolds, on the other hand, were made using electrospinning, creating a network of fibers with an average width of 4.5 micrometers. These fibers help to align cells in a way that mimics the structure of natural muscle tissue, which is important for achieving the texture of real meat.

Viable for large-scale production

Tests on these scaffolds showed that chickpea protein supports the growth of both bovine mesenchymal stem cells (bMSCs) and skeletal muscle cells (SMCs), with cells attaching, proliferating, and expanding successfully. Notably, the aligned fibers in the fibrous scaffolds encouraged skeletal muscle cells to orient in the same direction, similar to the way muscle tissue forms naturally. This feature is crucial for replicating the texture and appearance of traditional meat.

The electrospray and electrospinning techniques used to create these scaffolds are not only effective but also scalable, making them viable for large-scale cultivated meat production.

In addition to supporting cell growth, chickpea protein retains its nutritional value, which could enhance the final cultivated meat product. The protein also exhibited functional properties such as solubility, gelling, and emulsification, contributing to the stability and texture of the scaffolds and the overall product.

One of the key challenges in cultivated meat production is finding materials that are affordable, scalable, and free from animal-derived ingredients. The use of chickpea protein addresses these challenges by providing a plant-based, sustainable alternative to traditional animal-derived scaffolding materials like collagen and gelatin.