Kynda Opens Industrial Fermentation Site to Scale Protein from Food Sidestreams

Kynda, a biotechnology company specializing in fermentation-based protein production, has opened a new research and production facility in Jelmstorf, Lower Saxony. The 720-square-meter site combines laboratory and production operations, with the aim of converting underutilized food processing sidestreams into fungal mycelium for use as protein. The facility includes 360 square meters of R&D space focused on process optimization and substrate adaptation, alongside a production area with 40,000 liters of fermentation …

Liberation Bioindustries Restructures Leadership as Indiana Facility Nears Completion

Liberation Bioindustries has restructured its executive team, with co-founder Etan Bendheim stepping into the role of Chief Executive Officer, while fellow co-founder Mark Warner transitions to Chief Technology Officer. The change comes as the company approaches the operational launch of its first commercial-scale precision fermentation plant in Richmond, Indiana. Technical focus takes priority Warner, who previously served as CEO, will now focus on technical execution and infrastructure development. “This transition …

Nurasa Integrates New Wave Biotech’s Simulation Software to Advance AI-Driven Biomanufacturing Scale-Up

UK-based software company New Wave Biotech has entered into a commercial partnership with Singapore’s Nurasa to integrate AI-driven bioprocess simulation into the latter’s food innovation infrastructure. The collaboration is intended to provide earlier-stage companies with tools to evaluate the technical and economic feasibility of scaling precision fermentation and other biomanufacturing processes. Virtual testing before physical investment Under the agreement, companies within Nurasa’s network will gain access to New Wave Biotech’s …

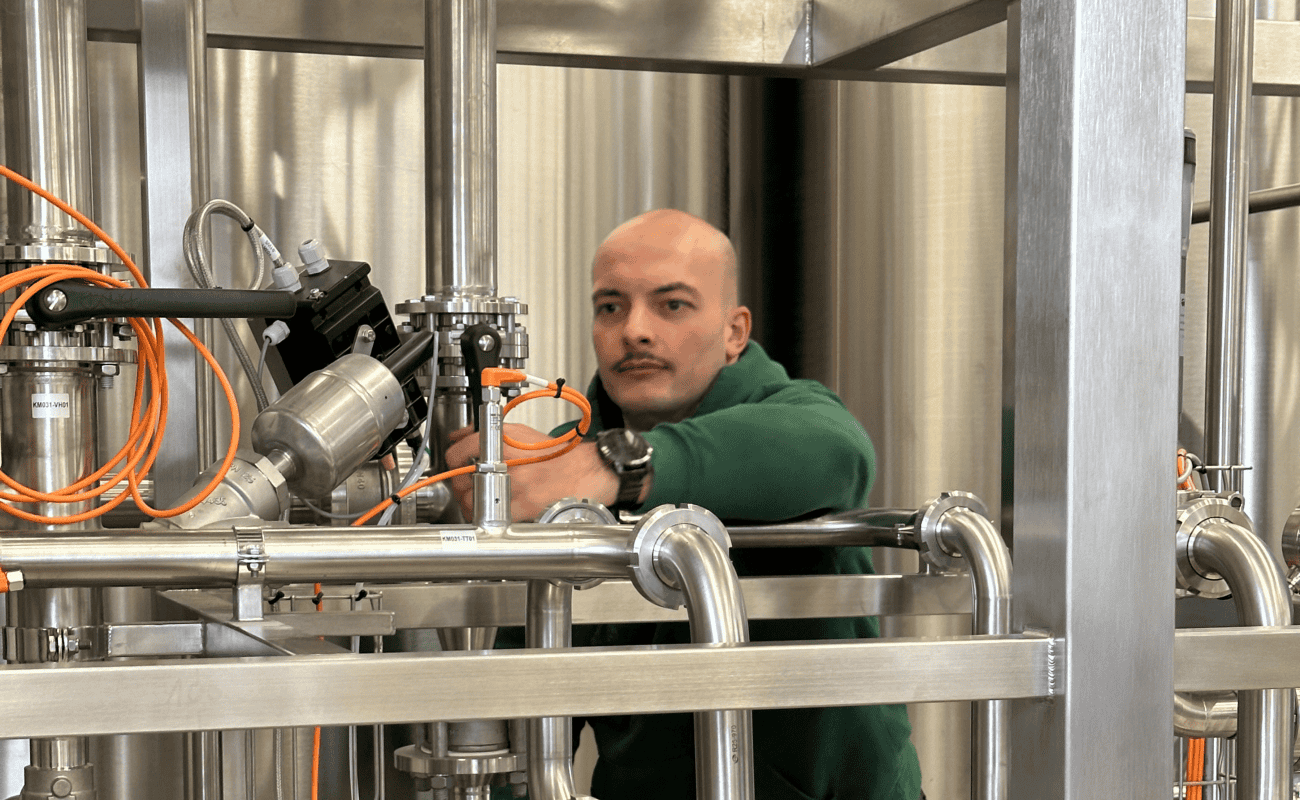

GEA to Equip Open-Access Fermentation Pilot Line at NIZO Campus

Engineering group GEA has been contracted to supply and commission a precision and biomass fermentation upscaling line for the Biotechnology Fermentation Factory (BFF), located at the NIZO Food Innovation Campus in Ede, Netherlands. The installation is planned for 2026, with pilot-scale operations expected to begin in spring 2027. The facility is intended to support food and ingredient companies in validating and scaling fermentation-based processes for applications including animal-free dairy proteins, …

Brazil’s Typcal Inaugurates New Facility for Its Sustainable Mycoprotein

Typcal, a Brazilian producer of sustainable mycoprotein ingredients, has announced the inauguration of a new production facility in the municipality of Pinhais, part of the Metropolitan region of the city of Curitiba. The facility will allow Typcal to commence commercial-scale production, which could enable the company to begin selling its ingredients in Europe and Latin America by next year. Typcal will initially offer fresh and powdered mycoprotein products, but is …

Solar Foods Reveals Location of Its First Industrial-Scale Production Facility

Air-based protein producer Solar Foods has chosen a site in Selkäharju, Lappeenranta, Finland, as the location of its first industrial-scale production facility, Factory 02. Solar Foods’ existing facility, Factory 01, can produce 160 tons of protein annually; Factory 02 will significantly increase this capacity to 6,400 tons per year. The final investment decision regarding the construction of the new facility is expected to be made in 2026. Solar Foods considered …

FoodNavigator Reveals Top 30 Food-Tech Innovators of 2025

FoodNavigator has released its list of the 30 most innovative food-tech companies, selected from 78 entries in its 2025 Global Food Tech Awards. The selection reflects a strong focus on technological responses to challenges such as supply chain instability, nutritional deficits, resource scarcity, and environmental degradation. Fermentation and artificial intelligence dominated the field, alongside a growing emphasis on bioactive functionality in ingredients. The awards examined companies across three regions—EMEA, the …

South Korea’s SeaWith Partners with 3D Bio-Tissues to Lower Cultivated Meat Costs

UK-based biotech company 3D Bio-Tissues (3DBT), a subsidiary of BSF Enterprise PLC, has signed a commercial supply agreement with South Korean cultivated meat developer SeaWith. The deal will see 3DBT supply its proprietary cell culture supplement, City-Mix®, to support SeaWith’s cultivated beef production. £300,000 deal to support scale-up The agreement, valued at approximately £300,000, establishes a regular shipment of City-Mix® to SeaWith. The product is designed to improve cell growth …

Joes Future Food Commissions “China’s Largest” Cultivated Meat Pilot Plant

Chinese cultivated meat producer Joes Future Food has announced the commissioning of what is claimed to be the country’s largest cultivated meat pilot plant. The company has also completed a scaled trial production of cultivated pork in a 2000-liter bioreactor, a move that has been described as a world first. The pilot facility integrates a complete technological chain, from cell line development and low-cost serum-free media to large-scale bioprocessing. This …

ProteinDistillery’s Facility Becomes a “Protein Competence Center”, Supporting Companies With Food Ingredient Production

ProteinDistillery, a scale-up using a patented process to transform biomass sources into functional protein, has announced that its facility in Heilbronn, Southern Germany, will become a Protein Competence Center from January 2026. The FSSC 22000-certified facility will be transformed into a hub for production and R&D collaborations relating to food ingredients and novel foods. It will be designed to support companies, including start-ups and scale-ups, from prototypes through to commercial production. The …